Quality & Inspection

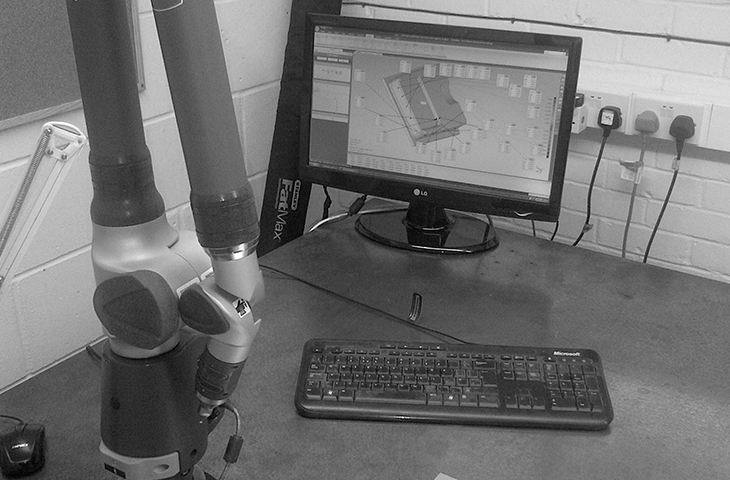

We have a full set of calibrated measuring equipment including a FARO inspection arm with powerful Geomagic Probe software to compare parts, moulds or patterns to 3D CAD models. This ensures that all parts leave the factory to the correct specification and required quality. We can provide 100% inspection reports. We can work with you to help specify quality inspection documents or simple drawings for your use and ours, allowable cosmetic and functional tolerances and master-part-signed quality limit samples.

We have a white light 3D scanner again can be used for scanning, measurement and reverse engineering of components. Basic 1st Article inspections or Full inspection and First article inspection reports (FAIR) and certificates of conformance (COC) can be produced for each part or samples from batches if required. We have also worked with several large OEMs and are familiar with (PPAP) Production Parts Approval Process.