Air Box Selection Guide

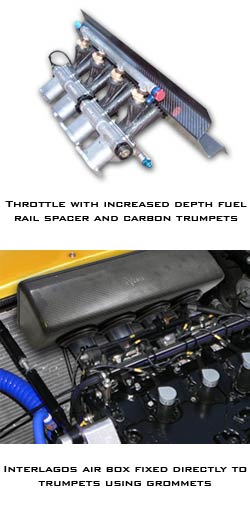

If you are using throttle bodies on a normally aspirated engine then pick an air box from our vast range based primarily on your fitting constraints, try and fit in the largest air box volume you can, allow for some engine movement. If you want to use a single throttle body on the air box for N/A or forced induction then be sure to select a plenum rather than an air box. Think carefully about the position of your fuel rail (on fuel injection systems), if it overhangs the trumpet mounting face, you will need a fuel rail spacer type back plate or use our air box trumpet grommets and brackets to have the air box sit and seal around the trumpets instead.

Consider the type of filter you want, if you want a filter inside the air box then consider a Silverstone or Zolder 112 (so long as you have 78mm - 112mm of depth from the mounting face), or use any of our air boxes with filters or filter boxes or for lower horsepower outputs internal foam trumpet socks singles or pairs.

Decide on the inlet diameter you wish to use. As a rule of thumb, bigger air box volumes and inlet diameters are better so that the engine is under atmospheric conditions, and tuned lengths are then just controlled by the inlet runners.

Our simple recommendations for intake sizing are a single 75mm diameter up to 210 BHP, 100mm diameter is ok to around 280Bhp, 127.5mm to 152mm recommended for 280 BHP+ or multiples of smaller diameter inlet pipes giving the same or larger open surface areas. Multiple smaller inlets allow for difficult packaging best seen on the OEM caterham R500 air box system (4 off 58mm tubes for 230 BHP). Noise reduction is increased when using our Porous sound absorbing ducting and also multiple smaller size inlets can allow for some bottom end torque tuning.

Inlet Sizing

An inlet that is too small will cause a pressure drop inside the air box restricting performance. The inlet sizing guide (below) shows the minimum recommended inlet and ducting size for a power output category. The larger the power output of an engine the more air it will require to run at peak efficiency, therefore a larger inlet pipe/duct is needed as power increases. Multiple smaller inlet pipes/ducts can be used to achieve the same open area as a larger inlet, for example, if a larger inlet pipe/duct won’t fit on the air box, multiple smaller pipes or oval inlet pipes could be used to create a comparable open area. High flow alloy straight trumpets can also be used as intakes.

BHP Category | Open Area (cm²) | Inlet Diameter (mm) |

1 - 150 | 44.18 | 75.0 |

150 - 205 | 56.75 | 85.0 |

205 - 265 | 78.54 | 100.0 |

265 - 325 | 127.68 | 127.5 |

325 + | 181.46 | 152.0 |

On typical engines 150CFM is required for each 100BHP

On high performance engines 130CFM is required for each 100 BHP

The formula below shows the formula for required airflow to the engine in cubic feet per minute.

CFM = Engine Capacity (Cubic Inches) / 3464 * Max RPM

1L = 61.0237in³

For example a 5.7 litre engine requires 703CFM of air at 7000rpm :

703 CFM = 347.84CI / 3464 * 7000RPM

Or if supercharged...

CFM = (CI * RPM / 3456) * (boost [psi] / 14.7 + 1)